Keep control,

guarantee quality

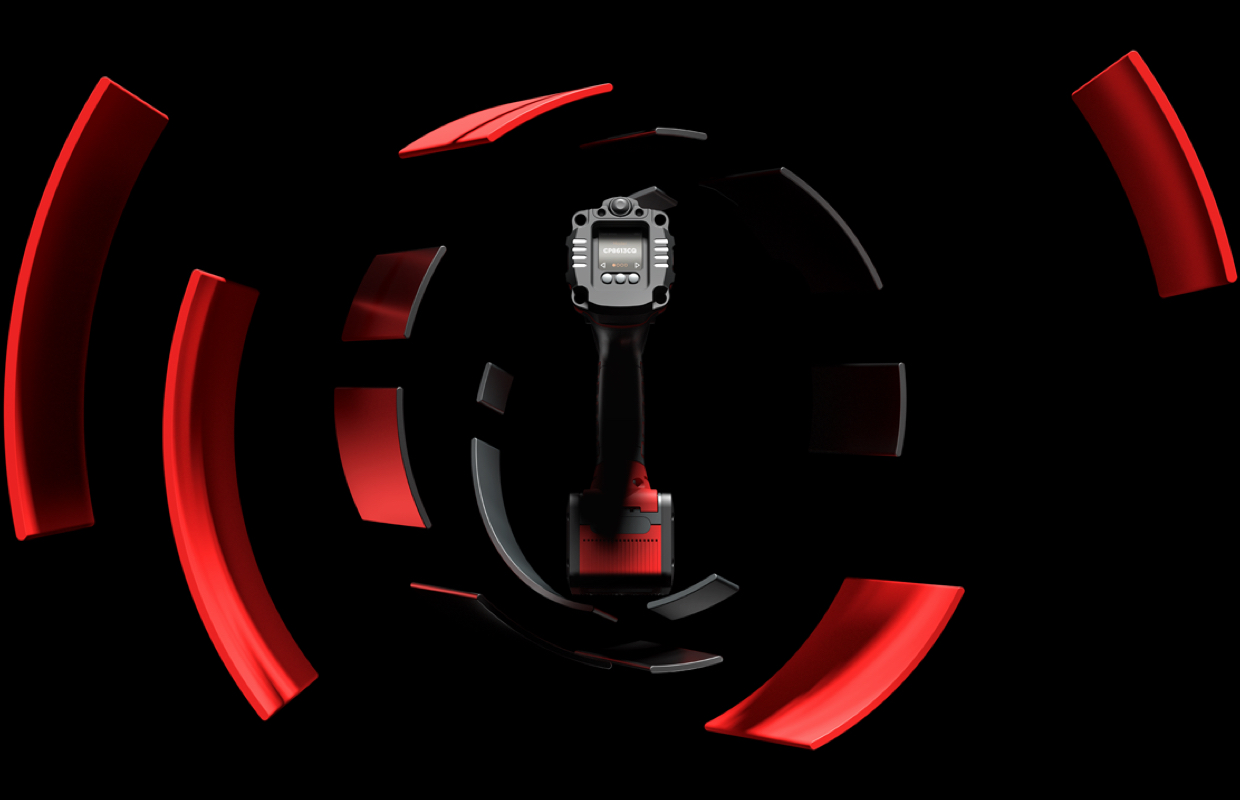

CPLinQ is an application specifically dedicated for managers looking to control processes and quality in the field, while improving productivity.

This is the unique solution to set up, control, report and maintain your jobs, with data collection and sequence set-up.

Increase your productivity

- Save time on every operation

- Decrease errors and rework

- Get back to service faster

- Reinforce company quality standards

Optimize processes and quality in the field

Control your job tightening and sequences

P-Set library

100% tightening guarantee

0% rework

Torque check for 100% control of bolt loosening

Maintain your tool

Decrease the risk of breakage with:

- Tool status follow-up management

- Operation alert

- Maintenance timeline

Report your jobs

Tightening report for a quick report and data export

Lock & finder

Lock your tool to prevent theft and accidents

The CP86 Series in videos

Discover the CP86 Series

Discover the CP86 eBlueTork Series

Frequently asked questions

You will see time, date, torque/angle result and/or counting sequence result, result root cause, tightening time, and torque unit.

From CPLinQ, you can very quickly distribute the .xls report from your mobile device (both Android and iOS/iPhone/iPad) using a messaging app or by email.

It is easy to define the number of cycles or the operating time directly in the tool menu. It is also possible to use the connected version with CPLinQ to create alerts for preventive maintenance or to subscribe to a CPCare Preventive Maintenance contract to extend the tool’s working life by up to 20%.