Optimisez la performance et la sécurité de votre flotte !

- Standardiser vos processus

- Simplifier les tâches des techniciens pour faciliter leur travail

- Contrôler toutes les opérations afin de réduire les erreurs

- Éliminer les tâches redondantes pour une plus grande efficacité

Optimisez le contrôle de votre maintenance

La sécurité, une priorité

Sécurisez l'ensemble de votre flotte de véhicules ! Grâce à l'automatisation des processus de serrage, les risques de détachement des roues sont diminués.

Piloter par la donnée

Enregistrez chaque opération de serrage pour une traçabilité complète.

Efficacité optimisée

Améliorez votre productivité en standardisant les processus et en guidant précisément les opérateurs pour éviter les erreurs

Réalisez votre maintenance en 3 étapes

Préparer la maintenance

Préparer le travail avec précision

Configurez et intégrez tous les paramètres de votre flotte de véhicules dans votre base de données Info Hub. Les instructions seront envoyées à l'opérateur.

Exécuter la maintenance

Exécuter sans erreur dès la première intervention

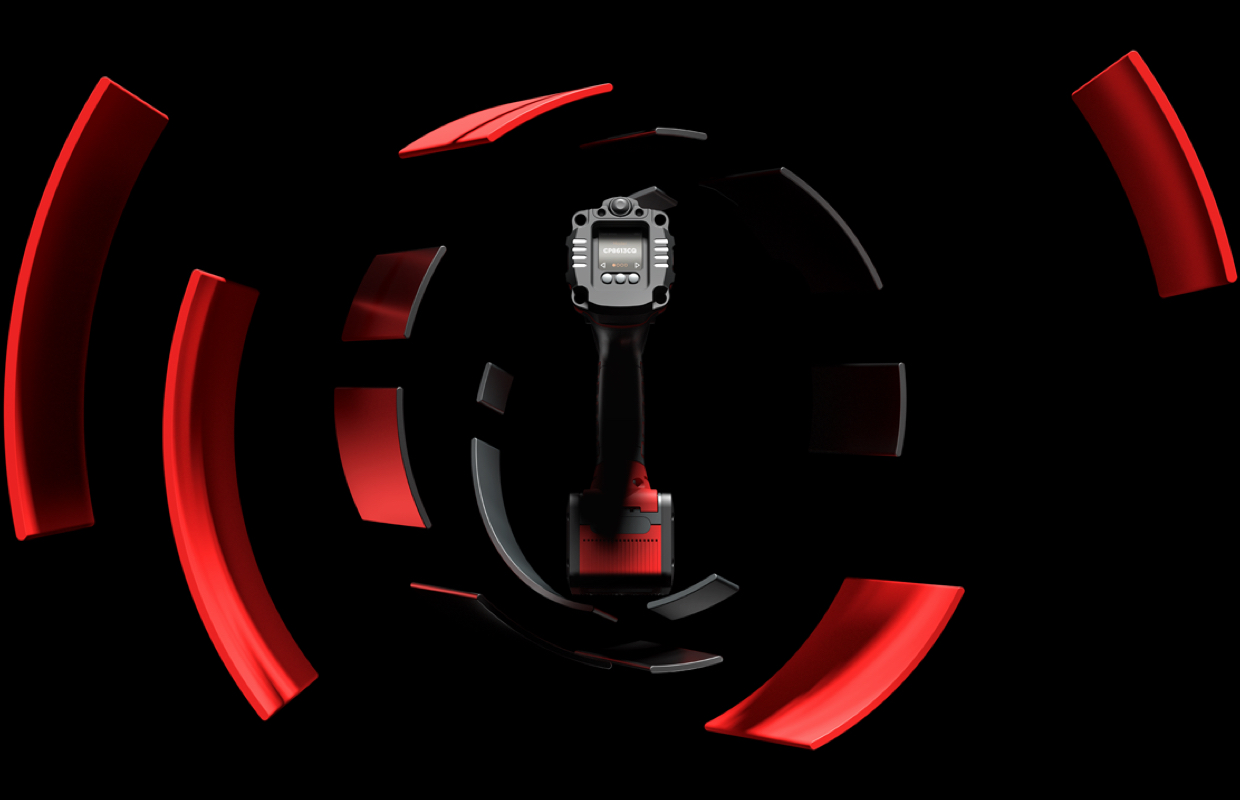

Les opérateurs connectent l'outil eBlueTork à l'application CPLinQ PRO HTB et suivent les instructions étape par étape directement sur l'appareil.

Vérifier l'exécution

Contrôler les données

Analysez les données de la flotte pour vérifier chaque véhicule et identifier les prochaines étapes ou les mesures correctives à prendre.

Découvrez plus en détail CPLinQ PRO HTB

À votre service pour vous guider avec CPLinQ PRO HTB !

- Installation et mise en service

- Assistance experte : assistance à distance et sur site

- Maintenance et calibration