Learn more

Get your questions answered

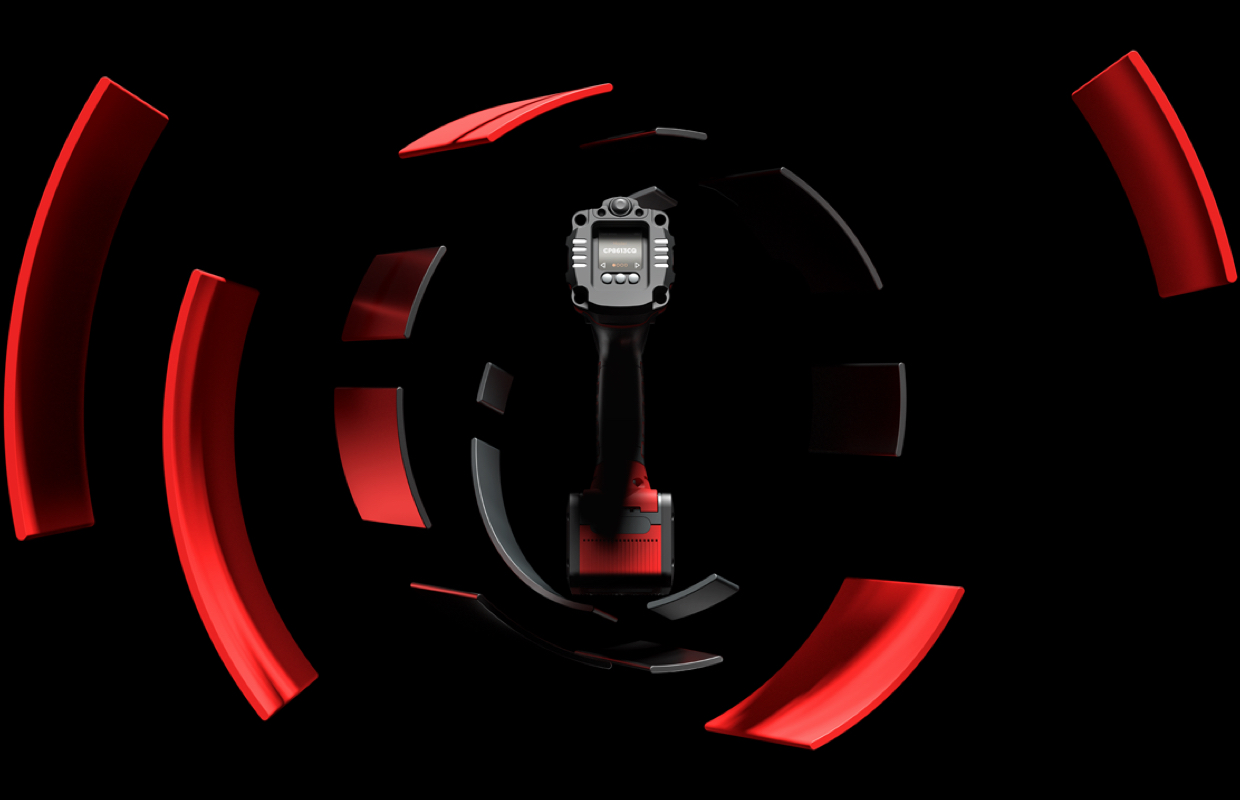

Please fill out the form to learn more on CP86 eBlueTork and CP86. We will be in touch with you shortly.

Extended range with 5 torque levels available in 4 versions

- Standalone version to get the job done

- Connected version for control and tool maintenance follow-up

- Connected quality version for process control and traceability

- Torque check version for process quality control

|

|

|

|

||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

Perform Stand-alone

All models

|

Control & Maintain C-Connected

All models

|

Control, Maintain & Report CQ - Connected Quality

All models

|

Control, Maintain, Report & ProcessTC – Torque Check

CP8613 / CP8626 / CP8641 / CP8681 / Cp8609 eBlueTork

|

||||||||||||||||||||||||||||||||

| Performance |

|

||||||||||||||||||||||||||||||||||

| Safety |

|

||||||||||||||||||||||||||||||||||

| Connectivity |

|

||||||||||||||||||||||||||||||||||

| Tool Maintenance |

|

||||||||||||||||||||||||||||||||||

| Job Control |

|

||||||||||||||||||||||||||||||||||

| Report |

|

||||||||||||||||||||||||||||||||||

| Process control |

|

||||||||||||||||||||||||||||||||||

Customer benefits payback

Does the double safety trigger come as standard?

At Chicago Pneumatic, we believe that worker safety is the most important priority, so all tools come with a fully integrated dual trigger as standard. If you prefer the tool without the double safety trigger, we can modify it to your requirements. Please contact our Customer Service Team. Read more

Can I use my tool as a standalone solution even if it is a connected version?

You can switch from Favorite to Open set-up easily. All tightening actions are recorded in the CQ version when operating in the open set-up mode.

How many cycles can I achieve with one battery charge?

Battery life is very much dependent on the joint type and the working temperatures. The range can be quite wide but it can also be optimized by the tightening strategy used to program the tool.